E-Waste Recycling: Recovering Precious Metals

Electronic waste continues to grow exponentially as technology advances and consumer demand increases. Discarded devices such as smartphones, computers, and appliances contain valuable precious metals that, if properly recovered, offer significant environmental and economic benefits. The process of extracting these metals plays a critical role in responsible waste management and resource conservation. A professional waste management company is key to unlocking this value while ensuring compliance with environmental and safety standards.

Understanding Precious Metals in E-Waste

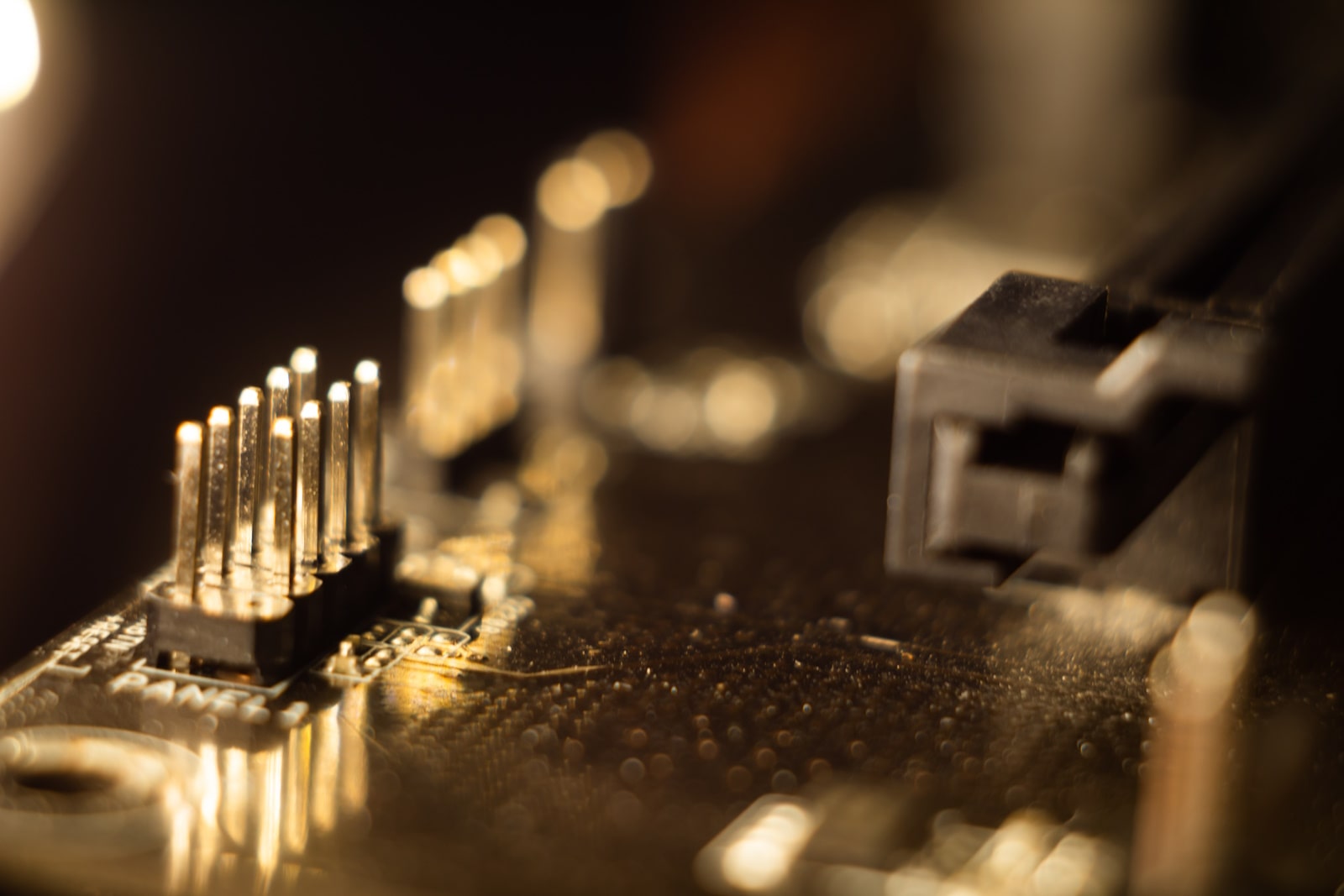

Electronic waste is a rich source of precious metals including gold, silver, palladium, and platinum. Gold is extensively used in connectors, microchips, and circuit boards due to its exceptional conductivity and resistance to corrosion. Silver’s high conductivity makes it indispensable for switches, soldering, and batteries. Palladium, found mainly in capacitors and connectors, is crucial for maintaining electronic device performance, while platinum’s stability and resistance to heat make it valuable for components like hard disk drives. The recovery of these metals not only offsets the cost of recycling but also reduces the reliance on environmentally destructive mining activities. Waste management companies leverage this metal content to generate revenue and promote sustainable practices.

The presence of such precious metals in e-waste makes it an increasingly attractive resource for recycling. Globally, the value locked in e-waste metals is estimated to reach billions of dollars annually. For South Africa, with its growing electronic consumption and strict waste regulations, recovering these metals is both an environmental imperative and an economic opportunity. Efficient recovery of precious metals reduces the volume of hazardous waste entering landfills, making the role of a reliable waste management company indispensable in this process.

Collection and Sorting of E-Waste

Effective e-waste recycling begins with well-organised collection and sorting strategies. Collection points, drop-off centres, and take-back programmes offer convenient ways for households and businesses to dispose of obsolete electronics. Waste management companies often coordinate curbside pickups or collaborate with manufacturers and retailers to facilitate responsible disposal. The integrity of this initial step is vital to prevent e-waste from entering informal or illegal recycling streams that cause environmental harm.

Sorting processes involve separating valuable metal-containing components from non-recyclable materials. Manual sorting by trained personnel is complemented by mechanical separation methods such as shredding, magnetic separation, and eddy current separation. More advanced waste management companies are now incorporating artificial intelligence and automated sorting technologies to enhance accuracy and efficiency. Proper sorting maximises the recovery of precious metals and minimises contamination, enabling downstream chemical extraction processes to be more effective and environmentally sound.

Physical Dismantling Techniques

Once e-waste is collected and sorted, physical dismantling becomes the focus to isolate metal-rich components. Manual dismantling requires skilled workers to carefully remove circuit boards, connectors, batteries, and wiring, preventing damage to recoverable metals. This hands-on approach is particularly useful for high-value or delicate parts but can be labour-intensive.

Mechanical dismantling offers scalability and speed through the use of shredders, crushers, and separators that break down electronics into manageable fragments. These processes expose the metals for further separation and chemical recovery. Waste management companies often combine manual and mechanical techniques to optimise metal extraction while ensuring worker safety. Proper dismantling is essential to prevent hazardous materials from contaminating recovered metals and to comply with South African health and safety regulations.

Chemical Extraction Methods

Physical processes alone cannot recover all precious metals from e-waste; chemical extraction methods are crucial for effective recovery. Hydrometallurgical techniques use aqueous solutions to leach metals from shredded electronic components. These solutions often contain acids or cyanide-based compounds designed to selectively dissolve specific metals. Pyrometallurgical methods, involving high-temperature smelting and refining, are also employed to separate metals from impurities.

Innovative and environmentally friendlier approaches such as bioleaching are gaining attention. Bioleaching uses specialised microorganisms to extract metals, reducing chemical use and environmental impact. Waste management companies adopting these emerging technologies can offer safer and more sustainable recycling solutions. However, these methods require strict control measures to prevent chemical pollution, making regulatory compliance a key focus area.

Environmental Impacts and Mitigation

While recovering precious metals from e-waste offers many benefits, improper recycling can result in significant environmental pollution. Toxic substances such as lead, mercury, and cadmium present in electronic devices can contaminate soil and water if mishandled. Waste management companies must implement closed-loop systems that minimise emissions and waste discharge during metal recovery processes.

South Africa’s National Environmental Management: Waste Act (NEMWA) and related regulations mandate strict environmental controls for e-waste recycling operations. Adhering to these standards not only protects ecosystems but also ensures legal compliance. Waste management companies prioritise mitigation strategies including proper hazardous waste handling, air filtration, and effluent treatment to reduce the ecological footprint of metal recovery.

Economic Value of Recovered Metals

The recovery of precious metals from e-waste is not only environmentally responsible but also economically viable. Recycled metals can be sold in global commodity markets, providing a revenue stream that supports the operational costs of recycling facilities. This economic incentive motivates waste management companies to invest in advanced recovery technologies.

Additionally, the e-waste recycling sector creates jobs in collection, sorting, dismantling, and refining activities. South Africa’s growing electronic consumption means local recovery of metals reduces dependence on imported raw materials and contributes to economic development. Waste management companies operating within this framework support a circular economy by turning waste into valuable resources, benefiting both industry and society.

Emerging Technologies in Metal Recovery

Innovations are reshaping how waste management companies recover metals from e-waste. Bioleaching, which harnesses microorganisms to extract metals, offers a green alternative to traditional chemical methods. Green chemistry principles are also applied to develop less hazardous solvents and reagents for metal recovery.

Cutting-edge equipment with automated sorting, sensor-based separation, and robotics enhances precision and throughput, lowering environmental impact and improving safety. Adopting these technologies positions waste management companies at the forefront of sustainable e-waste recycling, driving South Africa toward its environmental goals.

Regulatory Challenges and Compliance

South Africa’s legislative framework for e-waste management is anchored in the Extended Producer Responsibility (EPR) system, which places responsibility on manufacturers and importers for the end-of-life management of their products. Waste management companies must align their operations with the National Environmental Management: Waste Act (NEMWA) and the e-Waste Regulations to ensure full legal compliance.

Regulatory challenges include meeting reporting requirements, maintaining proper documentation, and adhering to stringent health, safety, and environmental standards. Companies must also navigate evolving policies as the government intensifies efforts to formalise the e-waste sector. Partnering with a knowledgeable waste management company ensures these complexities are managed effectively.

Health and Safety in E-Waste Recycling

Protecting the health and safety of workers is paramount in e-waste recycling due to exposure to hazardous chemicals and materials. Waste management companies implement comprehensive safety protocols, including personal protective equipment, ventilation systems, and rigorous training programmes to minimise risks.

South African occupational health and safety regulations require adherence to strict standards, and ongoing monitoring is essential. Safe handling procedures not only protect workers but also reduce environmental contamination, ensuring responsible and ethical recycling practices.

Circular Economy and Resource Conservation

Recovering precious metals from e-waste is integral to advancing a circular economy where materials are continuously reused rather than discarded. By recycling electronic waste, waste management companies contribute to resource conservation, reduce mining pressures, and lower greenhouse gas emissions associated with raw material extraction.

This sustainable approach fosters economic resilience by creating green jobs and promoting responsible consumption patterns. South Africa’s commitment to the circular economy is reflected in its waste policies, which encourage the integration of e-waste recycling into broader resource management strategies.

At A-Thermal, we understand the critical role a waste management company plays in responsible e-waste recycling. Our expertise ensures compliance with South African laws while adopting innovative and sustainable metal recovery methods. Contact us today to learn how we can help you manage your e-waste safely and efficiently, contributing to a cleaner environment and a circular economy.